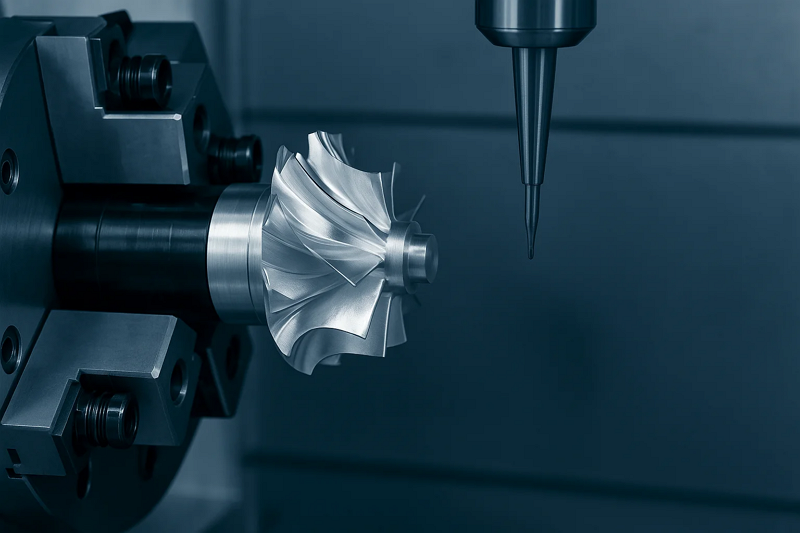

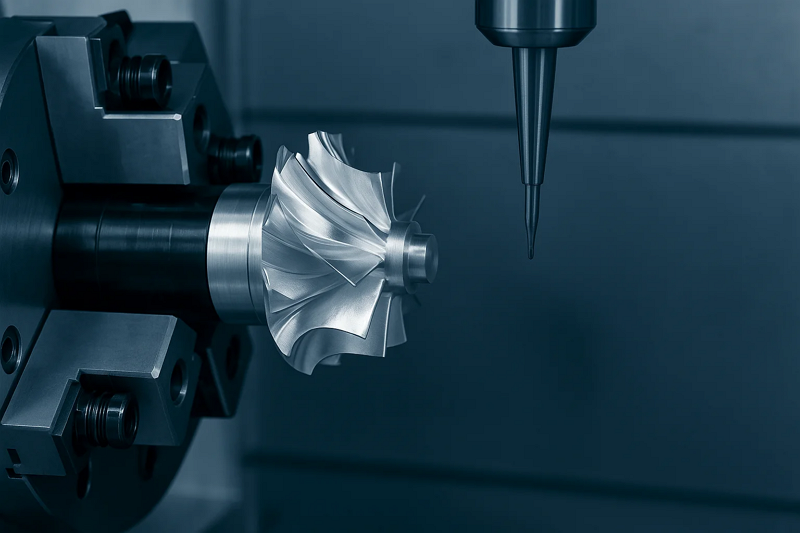

In modern manufacturing, CNC machine tools (CNC) are widely used in metal processing, automobile manufacturing, aerospace, mold manufacturing and other fields. As an indispensable auxiliary material in the processing of CNC machine tools, cutting fluid undertakes multiple functions such as cooling, lubrication, cleaning and rust prevention. Reasonable use of cutting fluid can not only improve processing quality, but also extend tool life and improve production efficiency. So, what are the functions of cutting fluid? This article will analyze it in detail for you.

1. Cooling effect-lowering temperature and avoiding thermal deformation

During the metal cutting process, the violent friction between the tool and the workpiece will generate a lot of heat. If the heat cannot be taken away in time, the temperature of the workpiece and the tool will rise rapidly, resulting in thermal deformation, reduced precision, and even tool burnout. Cutting fluid absorbs and transfers heat to effectively reduce the temperature of the cutting area, prevent workpiece dimensional errors caused by overheating, reduce thermal wear of the tool, and improve processing stability.

Different types of cutting fluids have different cooling effects. For example, water-based cutting fluid has good thermal conductivity and is suitable for high-speed cutting, while oil-based cutting fluid, although its cooling capacity is relatively weak, can provide better lubrication effect and is suitable for low-speed and high-precision processing.

2. Lubrication effect - reduce friction and improve processing quality

During the cutting process, the friction between the tool and the workpiece will affect the cutting force and accelerate tool wear. The lubricating components in the cutting fluid can form an oil film between the tool and the workpiece, reduce direct contact, reduce cutting resistance, and improve processing smoothness.

Good lubrication can effectively reduce the generation of cutting heat, while reducing burrs on the surface of the workpiece and improving the finish of the processed surface. Especially in the processing of difficult-to-process materials (such as titanium alloys and stainless steel), the lubrication effect is particularly important, which can significantly increase the tool life and reduce the risk of tool breakage.

3. Cleaning effect - chip removal and cooling, keep the processing area clean

During the cutting process, a large amount of chips, metal powder and oxides will be generated on the workpiece. If these impurities are not removed in time, it may cause the cutting tool to be blocked, scratch the workpiece surface, and even affect the normal operation of the machine tool. Cutting fluid can quickly flush away these chips and keep the processing area clean, thereby improving processing efficiency and quality.

In addition, cutting fluids with good cleanliness can also prevent chips from adhering to the surface of tools and workpieces, avoid unnecessary surface damage caused by secondary cutting, and improve the quality and consistency of the final product.

4. Anti-rust effect - protect workpieces and equipment and extend service life

Metal materials are easily oxidized and rusted when exposed to air for a long time, and the tools, workpieces and machine tools of CNC machine tools may also be corroded if they are damp or exposed to coolant for a long time. Therefore, many cutting fluids are added with rust inhibitors to form a protective film on the metal surface to prevent moisture and oxygen from directly contacting the metal, thereby delaying the occurrence of rust.

For workpieces that need to be stored for a long time or processed multiple times, cutting fluids with good rust-proof performance can effectively reduce secondary oxidation and improve product quality. For machine tools, good anti-rust effects can also help extend the service life of equipment and reduce maintenance costs.

5. Environmental protection and safety - reduce pollution and protect the health of operators

Traditional cutting fluids, especially some mineral oil-based cutting fluids, may produce harmful gases or waste liquids to pollute the environment during use. In addition, some cutting fluids may contain irritating chemical components, and long-term contact may affect the operator's skin or respiratory system.

In recent years, environmentally friendly water-soluble cutting fluids have gradually become the mainstream of the market. This type of cutting fluid can not only reduce the generation of oil mist and smoke, but also reduce pollution to the environment. At the same time, some high-end cutting fluids also use non-toxic formulas, do not contain harmful substances such as nitrite, and are safer and more reliable.

In addition, reasonable maintenance of cutting fluids, such as regular replacement, avoiding impurity contamination, and maintaining appropriate concentrations, can also effectively increase its service life and reduce waste fluid treatment costs.

6. Selection and management of cutting fluids-the key to improving processing efficiency

Different processing methods and materials have different requirements for cutting fluids. For example:

High-speed cutting: requires strong cooling capacity, and water-based cutting fluids are recommended;

Difficult-to-process materials (titanium alloys, stainless steel, etc.): require stronger lubrication performance, suitable for oil-based cutting fluids or high-performance synthetic cutting fluids;

Aluminum alloy processing: a special cutting fluid that is non-corrosive to aluminum should be selected to avoid black spots or corrosion.

In addition, the maintenance of cutting fluid is equally important. Here are some common management measures:

Keep the concentration stable: Too concentrated may affect the cooling effect, too thin may reduce the lubrication performance. It is recommended to use a concentration detector to monitor and adjust regularly.

Prevent pollution: Avoid impurities such as oil, dust, metal chips, etc. from mixing into the cutting fluid to avoid reducing performance or causing bacteria to grow.

Regular replacement: Cutting fluid used for a long time may deteriorate and should be replaced according to the recommendations of the machine tool manufacturer or cutting fluid supplier.

Use a filtration system: It can remove impurities in the cutting fluid, increase service life, and reduce the maintenance cost of the machine tool.